E-mail: [email protected]

E-mail: [email protected]

Time:2025-04-07

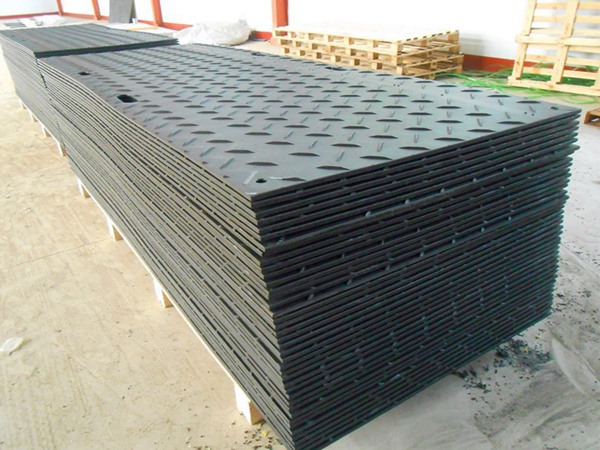

In construction sites, oil fields or large events, soft mud and uneven roads often become obstacles to the passage of construction vehicles and personnel. Although the traditional steel plate or concrete temporary road can solve the problem, it has some disadvantages such as high cost and inconvenient handling. In recent years, a new type of temporary paving pad has been gradually favored by the engineering community, which provides a more flexible solution for the construction site with its lightweight and durable characteristics.

Temporary paving pads are usually made of high strength composite materials or recycled plastic, weigh only 1 / 3 of the steel plate, but can withstand tens of tons of load. During the rainy season or wetland construction, laying pads can effectively disperse the pressure and prevent vehicles from falling into the mud. For example, when a wind power project transported the blades in the mountainous area, it successfully solved the problem of heavy machinery traffic by stitching the pads on the soft soil slope. This modular design can also be flexibly adjusted according to the terrain, especially suitable for pipeline laying, rescue and relief and other scenarios that need rapid passage.

Compared with traditional steel plates, temporary pavement pads avoid corrosion problems and have a service life of more than 10 years. The use of temporary paving pad without lifting equipment, two workers can complete the laying, this "ready to use" feature, especially suitable for short-term projects.

The application of temporary paving pad reflects the transformation of engineering construction from "extensive" to "fine". Its core value always lies in: with lighter "body", paving a temporary way for urban construction with high efficiency and environmental protection.