E-mail: [email protected]

E-mail: [email protected]

Time:2025-04-21

On modern construction sites, pump truck pouring operations are a common and critical part of the construction process. However, this process often comes with risks, especially on soft or insufficiently supported ground. Since pump trucks generate tens of tons of pressure while working, the stability of the outriggers becomes a key factor in ensuring the smooth operation of the equipment and construction.

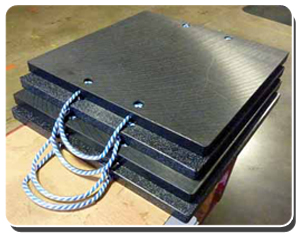

A new material, —— ultra-high molecular weight polyethylene leg pads, is gradually changing this situation. Traditional leg pads are mostly made of wood or metal. While they have the ability to bear pressure, their stability and reliability fall short in harsh working conditions, especially on soft ground, where they can easily sink or tilt, leading to serious accidents.

In contrast, ultra-high molecular weight polyethylene leg pads demonstrate advantages due to their physical properties. This material has excellent compressive strength and wear resistance, capable of evenly distributing the load applied on it, effectively preventing ground subsidence. Even under extremely harsh working conditions, it can maintain structural stability, significantly reducing the risk of equipment overturning.

In addition to mechanical properties, ultra-high molecular weight polyethylene leg pads also have good corrosion resistance and weather resistance, which is not affected by environmental factors and aging and deformation. This means that it can be used in a variety of complex environments for a long time, reducing maintenance costs and replacement frequency.